Unrivalled accuracy and speed

Secure a demo and experience firsthand how Hexagon’s advanced automated and in-process inspection solutions can redefine your manufacturing quality strategy.

Ready to get started?

Ready to get started?

Our Privacy Notice describes how we process Personal Data about you. It also provides information on how you may exercise any of your rights as a Data Subject. You have the right to withdraw your consent at any time by clicking on the "Unsubscribe" link within the electronic marketing communications sent to you. By submitting this form, you agree to our Terms of Use.

Transform production with automated manufacturing processes, improving efficiency and achieving consistent quality

In today’s fast-paced manufacturing environment, achieving consistent quality while optimising production processes is more critical than ever. Hexagon’s hardware and software portfolio of measurement and inspection solutions empowers quality teams to transition from reactive, end-of-line quality checks to proactive, real-time in-process optimisation.

Hexagon’s advanced solutions enable you to inspect, analyse, and improve production processes with unrivalled accuracy and speed. By integrating automated and in-process inspection into your manufacturing workflow, you not only detect defects early but also gain valuable insights to fine-tune your operations continuously.

Automated inspection reduces quality check times by up to 75%, accelerating production without sacrificing safety or quality.

Faster inspection, unparalleled accuracy

Proof points heading 2 - max 50 characters

Hexagon’s advanced portfolio—spanning state-of-the-art hardware and intelligent software—enables you to inspect, analyse, and improve production processes with unparalleled accuracy and speed. By integrating automated and in-process inspection into your manufacturing workflow, you not only detect defects early but also gain valuable insights to fine-tune your operations continuously.

- Aero structure manufacturing

- Acoustic simulation for cabin interior

- Metrology 3D hardware and software

- Digital twin manufacturing

Heading 4 - max 40 characters

Revolutionise the future of aerospace manufacturing with Hexagon.

Discover the technology behind cutting-edge aerospace production with our latest whitepaper.

Hexagon's precision metrology and digital continuity expertise will transform your production process from start to finish.

Empowering makers with innovative aerospace solutions

We deliver cutting-edge solutions for the aerospace industry that support transformation in aircraft design and accelerate innovation

Image size 1270x598

Realising a new standard in quality at every stage of the product cycle

A holistic approach to quality control

Solution detail - max 355 characters

CTA anchored to form at top of page = max 15 characters

Lower costs, less scrap, optimised machine performance

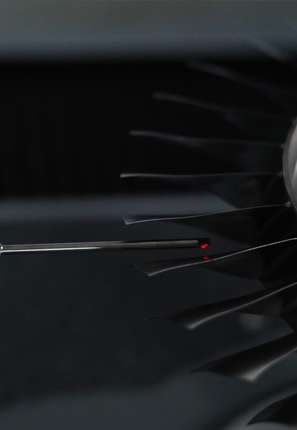

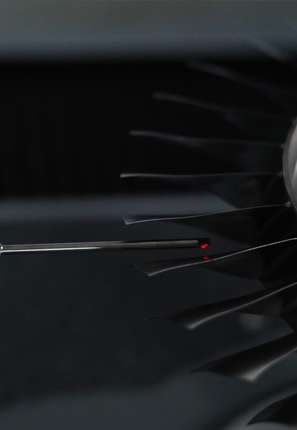

Greater accuracy, no more costly rework

By replacing manual inspections, automation minimises expensive rework due to undetected defects. By minimising scrap, reducing rework, and optimising machine performance, our solutions help you achieve significant cost reductions over the product lifecycle.

With in-process inspection, quality issues are identified as they occur, enabling immediate corrective actions. This reduces waste and prevents costly rework, ensuring that only compliant parts continue through the production cycle.

Image - 574x516

Case Study/whitepaper detail - max 290 characters

CTA to supporting article - max 15 characters

CTA - max 15 characters

Laser trackers & scanners

Ultra-precise, large-scale measurement systems for alignment, inspection, and 3D metrology.

Learn more➜

Portable inspection solutions

Flexible, high-precision metrology tools for on-the-go inspection and 3D measurement.

Learn more➜

Stationary inspection solutions

Advanced CMMs and software for automated, high-accuracy quality control in production.

Learn more➜

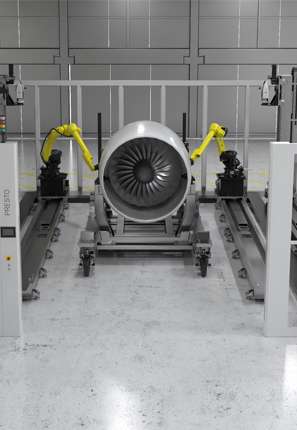

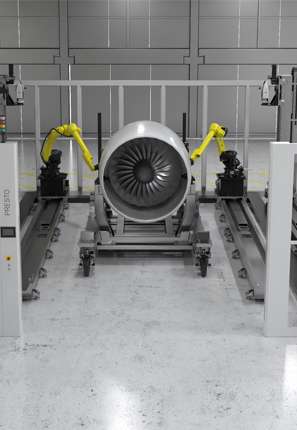

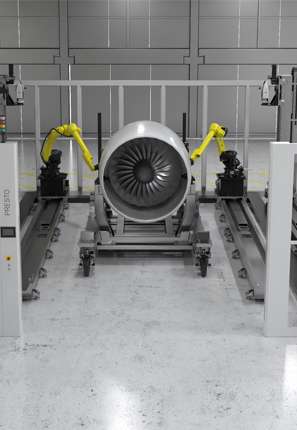

Automation inspection systems

Our PRESTO solution is designed to seamlessly integrate data from various inspection devices. It delivers real-time insights into process variability, ensuring that your production remains within tolerance and quality standards are met at every stage.

Learn more➜Realising a new standard in quality at every stage of the product cycle

Transform production with automated manufacturing processes, improving efficiency and achieving consistent quality

Unrivalled accuracy and speed

In today’s fast-paced manufacturing environment, achieving consistent quality while optimising production processes is more critical than ever. Hexagon’s hardware and software portfolio of measurement and inspection solutions empowers quality teams to transition from reactive, end-of-line quality checks to proactive, real-time in-process optimisation.

Hexagon’s advanced solutions enable you to inspect, analyse, and improve production processes with unrivalled accuracy and speed. By integrating automated and in-process inspection into your manufacturing workflow, you not only detect defects early but also gain valuable insights to fine-tune your operations continuously.

Automated inspection reduces quality check times by up to 75%, accelerating production without sacrificing safety or quality.

Faster inspection, unparalleled accuracy

Proof points heading 2 - max 50 characters

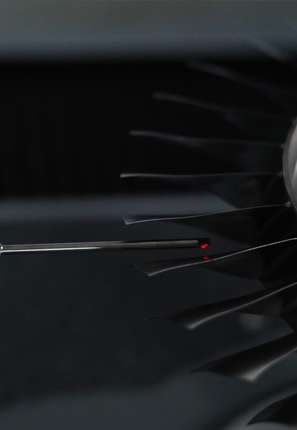

Image 1 - 369x208

Image 2 - 369x208

Image 3 - 369x208

Lower costs, less scrap, optimised machine performance

Greater accuracy, no more costly rework

By replacing manual inspections, automation minimises expensive rework due to undetected defects. By minimising scrap, reducing rework, and optimising machine performance, our solutions help you achieve significant cost reductions over the product lifecycle.

With in-process inspection, quality issues are identified as they occur, enabling immediate corrective actions. This reduces waste and prevents costly rework, ensuring that only compliant parts continue through the production cycle.

Hexagon’s advanced portfolio—spanning state-of-the-art hardware and intelligent software—enables you to inspect, analyse, and improve production processes with unparalleled accuracy and speed. By integrating automated and in-process inspection into your manufacturing workflow, you not only detect defects early but also gain valuable insights to fine-tune your operations continuously.

- Aero structure manufacturing

- Acoustic simulation for cabin interior

- Metrology 3D hardware and software

- Digital twin manufacturing

A holistic approach to quality control

Solution detail - max 355 characters

CTA anchored to form at top of page = max 15 characters

Image - 574x516

Laser trackers & scanners

Ultra-precise, large-scale measurement systems for alignment, inspection, and 3D metrology.

Learn more➜

Portable inspection solutions

Flexible, high-precision metrology tools for on-the-go inspection and 3D measurement.

Learn more➜

Stationary inspection solutions

Advanced CMMs and software for automated, high-accuracy quality control in production.

Learn more➜

Automation inspection systems

Our PRESTO solution is designed to seamlessly integrate data from various inspection devices. It delivers real-time insights into process variability, ensuring that your production remains within tolerance and quality standards are met at every stage.

Download➜Our Privacy Notice describes how we process Personal Data about you. It also provides information on how you may exercise any of your rights as a Data Subject. You have the right to withdraw your consent at any time by clicking on the "Unsubscribe" link within the electronic marketing communications sent to you. By submitting this form, you agree to our Terms of Use.

Our Privacy Notice describes how we process Personal Data about you. It also provides information on how you may exercise any of your rights as a Data Subject. You have the right to withdraw your consent at any time by clicking on the "Unsubscribe" link within the electronic marketing communications sent to you. By submitting this form, you agree to our Terms of Use.